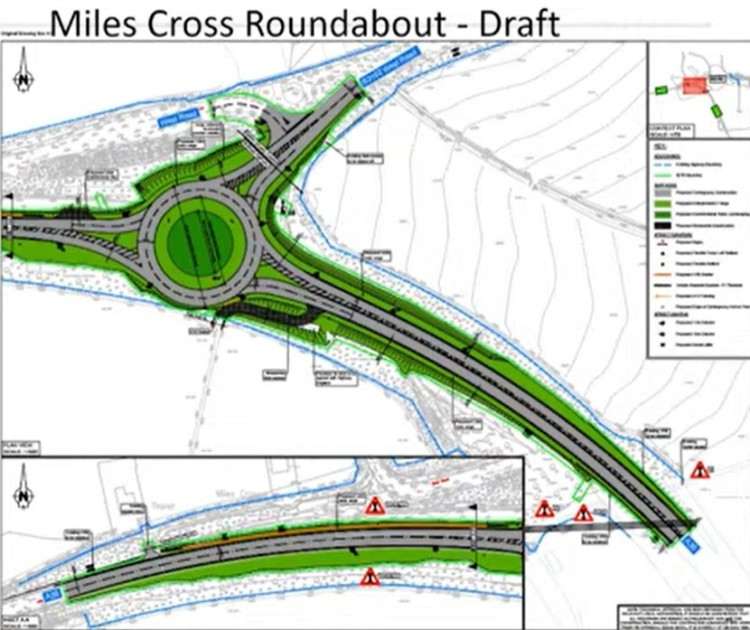

Take a look at Bridport's key and thriving industry

By Lottie Welch 22nd Nov 2020

Bridport's thriving rope and net making dates back to over 800 years, employing thousands of people.

With help from Bridport Museum, we're taking a look into the flourishing industry.

The earliest official record dates from around 1213 when King John ordered: "You cause to be made at Bridport, night and day, as many ropes for ships both large and small."

The growth of Bridport's key rope and net industry was due to the availability of two key raw materials - hemp and flax - with the soil perfect to grow them.

In the 14th century, both plants were cultivated throughout Dorset. By the end of the 18th century, most of the hemp and flax used here was imported through Bridport Harbour.

How were they made ready for rope and twine?

Beating

Farmers collected the seeds in the field from each plant after the outer skin had rotted away. They would lay a large sheet on the ground and 'beat' the hemp and flax with a wooden baton until the seeds feel onto the sheet.

The seeds were used for either planting or ground up to make oil.

Retting

After harvesting, both hemp and flax were spread on the ground to let the outer skins rot away, left out in the fields for six to eight weeks.

Moving to mills

Due to the Navy opening its own rope works at the Royal Dockyards, most rope making stopped in Bridport in 1610. But, Bridport's ropemakers instead focussed on making fishing lines, nets and sailcloth in their own homes and the spinning walks.

In the 1800s, the introduction of water-powered machines led to the building of flax spinning mills, such as Pymore Mill.

The Ackerman Loom, an electrically-powered 'jumper loom', was introduced in Bridport in the mid-1800s.

Sailcloth weaving moved into factories like Priory Mill in the 1850s. Hemp spinning and netting were also mechanised a decade later.

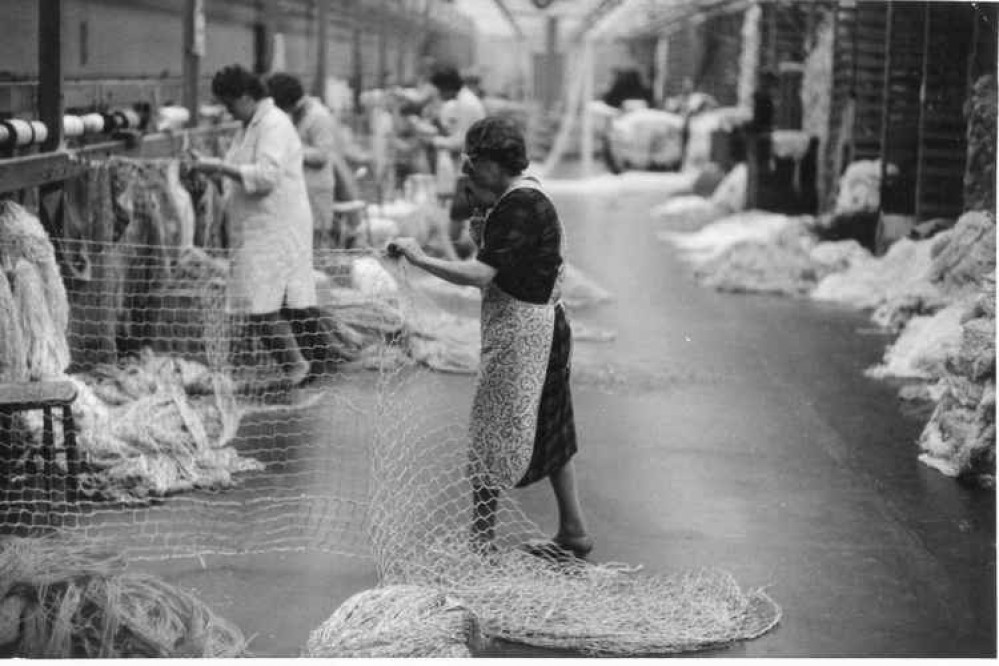

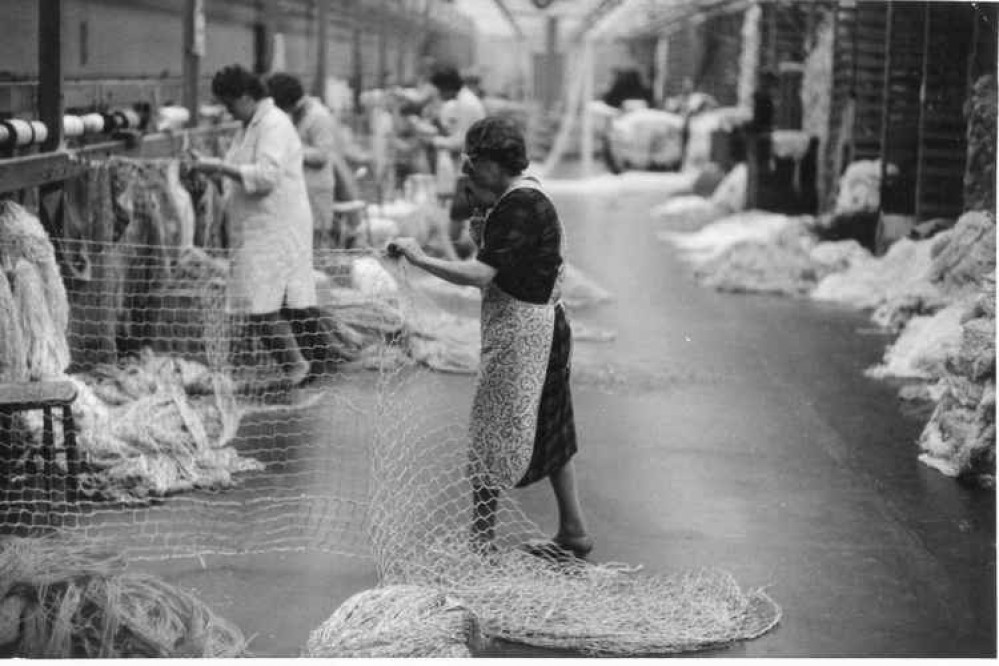

In 1963, all the independent net making factories in Bridport merged to form Bridport-Gundry, making sports nets, camouflage nets, air cargo nets and fishing nets.

Bridport-Gundry later became Amsafe, which is now a world leader in producing textiles for the aviation industry. There are also other netting firms, such as Huck Nets, in the town today.

Outworkers

There were some jobs that were too fine for factories and outworkers were employed to produce fine hard-braided net.

The work was mostly done by women and children, and each village came to specialise in a certain type of net.

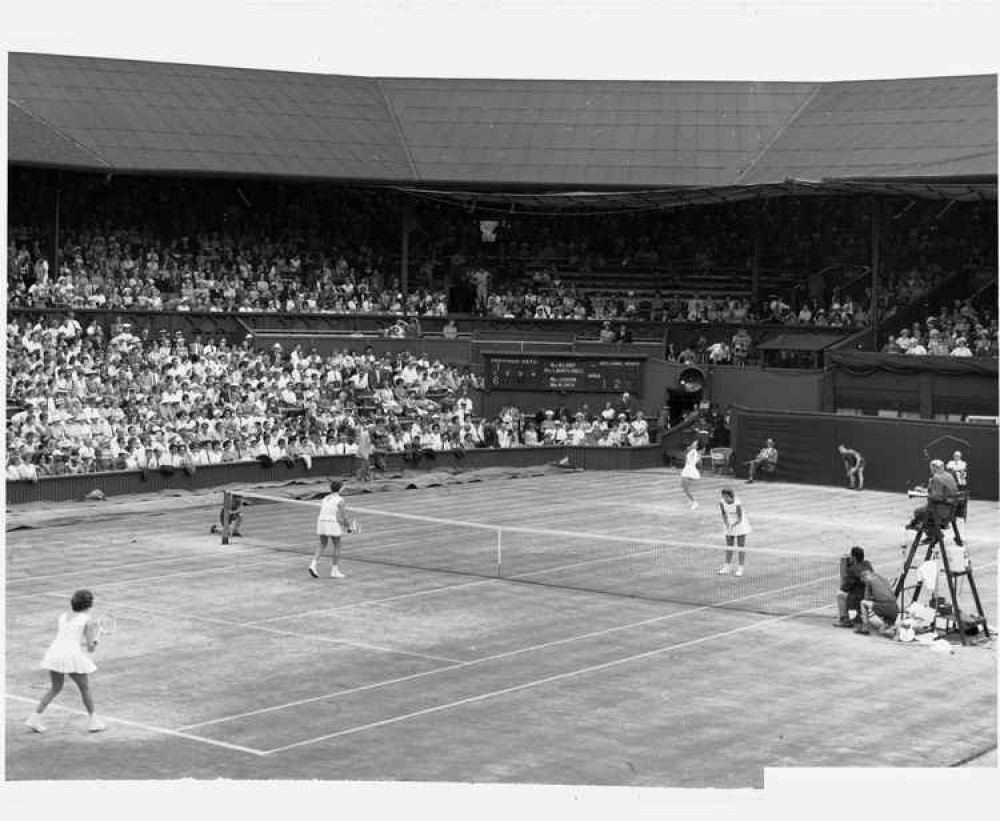

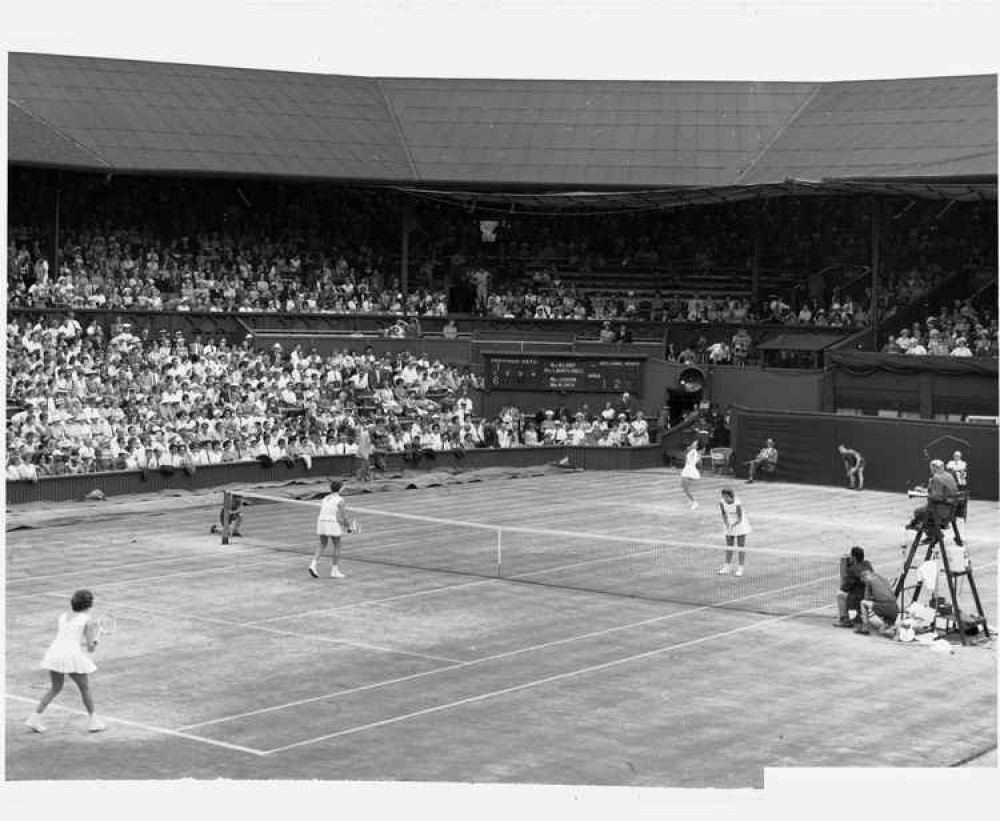

Bridport is a world leader in net production, with more than 10 companies in the town making nets that have a myriad of uses - from football pitches and Wimbledon to space shuttles and aviation.

Bridport Museum may be closed at the moment, but be sure to visit when it opens and discover even more about the town's rope and net industry.

If you have any memories or photographs of Bridport that you would like to share with us, email [email protected]

CHECK OUT OUR Jobs Section HERE!

bridport vacancies updated hourly!

Click here to see more: bridport jobs

Share: